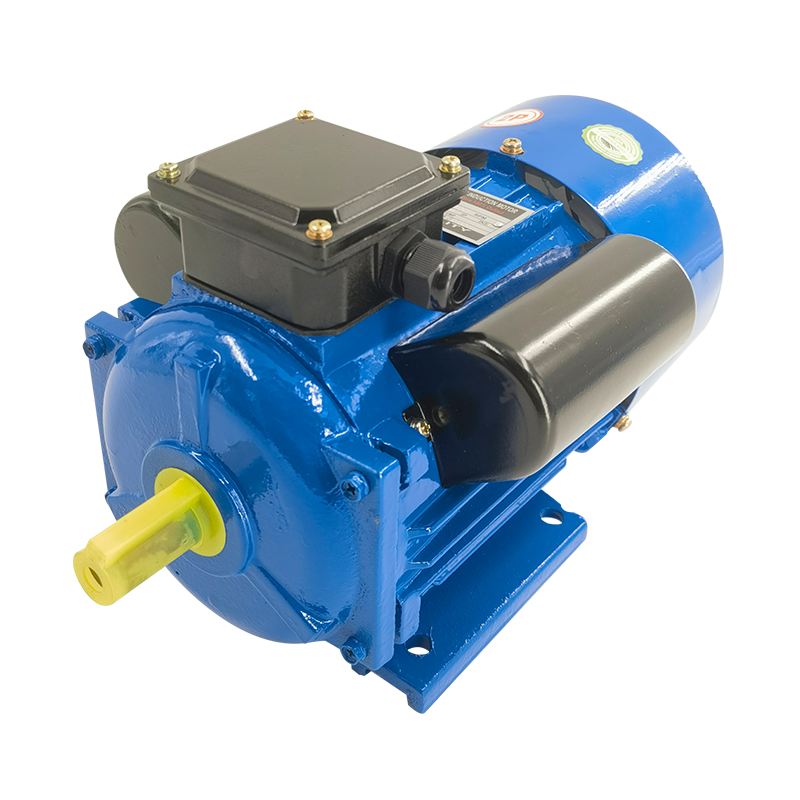

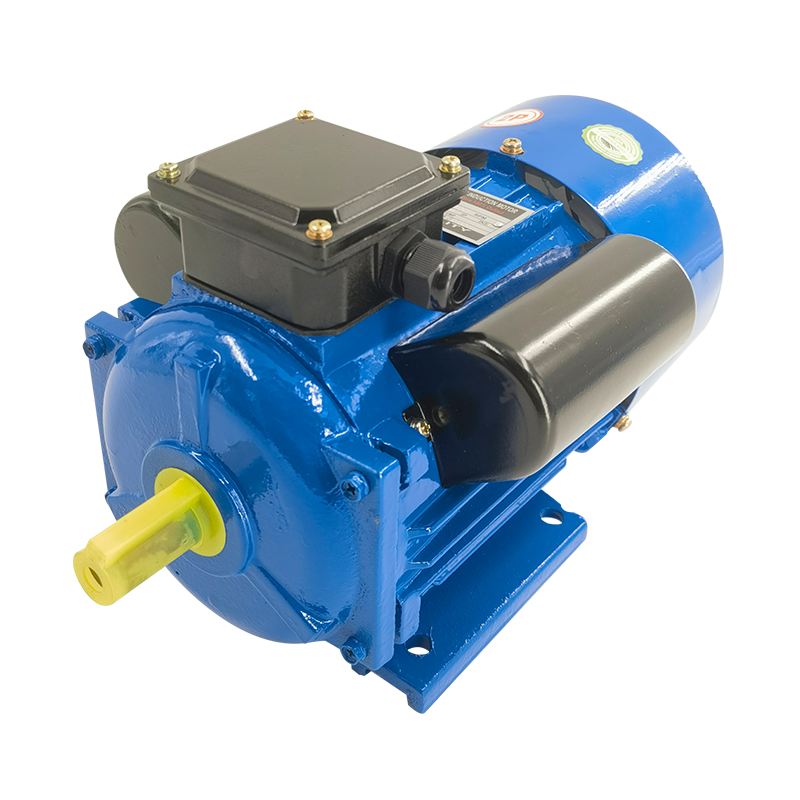

In recent years, the industrial motor market has experienced significant growth driven by advancements in efficiency, sustainability, and technological innovations. One of the standout developments is the rising use of the Double Value Capacitor Asynchronous Motor (DVCAM), a motor that offers exceptional performance and versatility in a wide range of industrial applications. This motor type, characterized by the integration of two capacitors in its design, is gaining widespread popularity due to its energy efficiency, improved torque performance, and long-lasting durability.

What is a Double Value Capacitor Asynchronous Motor?

A Double Value Capacitor Asynchronous Motor is a type of electric motor that utilizes two separate capacitors to improve its operational efficiency and starting performance. Asynchronous motors, also known as induction motors, operate on the principle of electromagnetic induction, where an electric current is induced into the rotor by the rotating magnetic field generated by the stator. The key distinction of the Double Value Capacitor Asynchronous Motor lies in the use of two capacitors: a starting capacitor and a running capacitor.

The starting capacitor is designed to provide a high starting torque, allowing the motor to start quickly and efficiently. The running capacitor, on the other hand, is used during the motor's normal operation to improve efficiency and ensure a smooth and continuous operation. This dual-capacitor design enables the motor to offer higher torque at startup and better overall efficiency compared to standard single capacitor motors, making it ideal for applications where both power and energy conservation are crucial.

Key Advantages of Double Value Capacitor Asynchronous Motors

The growing demand for Double Value Capacitor Asynchronous Motors can be attributed to several key advantages that make them highly suitable for a variety of industrial applications. These benefits include:

1. Improved Starting Torque

One of the significant advantages of the Double Value Capacitor Asynchronous Motor is its improved starting torque. The combination of a starting capacitor and a running capacitor allows the motor to generate higher torque during the startup phase compared to conventional asynchronous motors. This feature is particularly beneficial in applications where heavy loads need to be moved immediately, such as in compressors, pumps, and conveyor systems. The enhanced starting torque ensures that these motors can handle demanding workloads from the outset, to increased efficiency and reduced mechanical stress on equipment.

2. Energy Efficiency

The use of a running capacitor helps to improve the overall efficiency of the motor during operation. The running capacitor optimizes the power factor of the motor, reducing energy loss and ensuring that the motor operates at peak efficiency. As industries face increasing pressure to reduce energy consumption and minimize operating costs, energy-efficient motors like the DVCAM are becoming increasingly essential. The improved power factor and reduced energy consumption of these motors make them an choice for businesses looking to cut down on electricity usage and achieve more sustainable operations.

3. Reduced Maintenance Costs

Thanks to their high efficiency and reliable performance, Double Value Capacitor Asynchronous Motors also result in reduced maintenance costs. The dual capacitor design ensures that the motor operates smoothly, with minimal wear and tear on the internal components. As a result, these motors require less frequent servicing compared to conventional motors, to a longer operational lifespan and fewer disruptions to business operations. Reduced maintenance costs are particularly valuable in industries where machinery downtime can to significant production losses.

4. Cost-Effectiveness

While the initial cost of purchasing a Double Value Capacitor Asynchronous Motor may be higher than a standard single-capacitor motor, the long-term savings in terms of energy efficiency and reduced maintenance make it a highly cost-effective investment. The improved performance and energy savings provided by these motors offset their initial cost over time, making them an attractive option for businesses looking to reduce operating costs while maintaining high-performance standards. Additionally, the durability and reliability of these motors further enhance their cost-effectiveness by minimizing the need for replacements.

English

English Español

Español