In today’s industrial landscape, the importance of operational efficiency cannot be overstated. Businesses are under constant pressure to reduce downtime, minimize costs, and maintain high levels of productivity. As a result, the demand for equipment that is easy to maintain and repair has never been higher. The capacitor run asynchronous motor has emerged as a key player in this regard, offering a combination of high performance, ease of maintenance, and minimal operational disruptions. This motor type is proving invaluable in sectors where reliability and quick turnaround times are critical.

Simplifying Maintenance with Modular Design

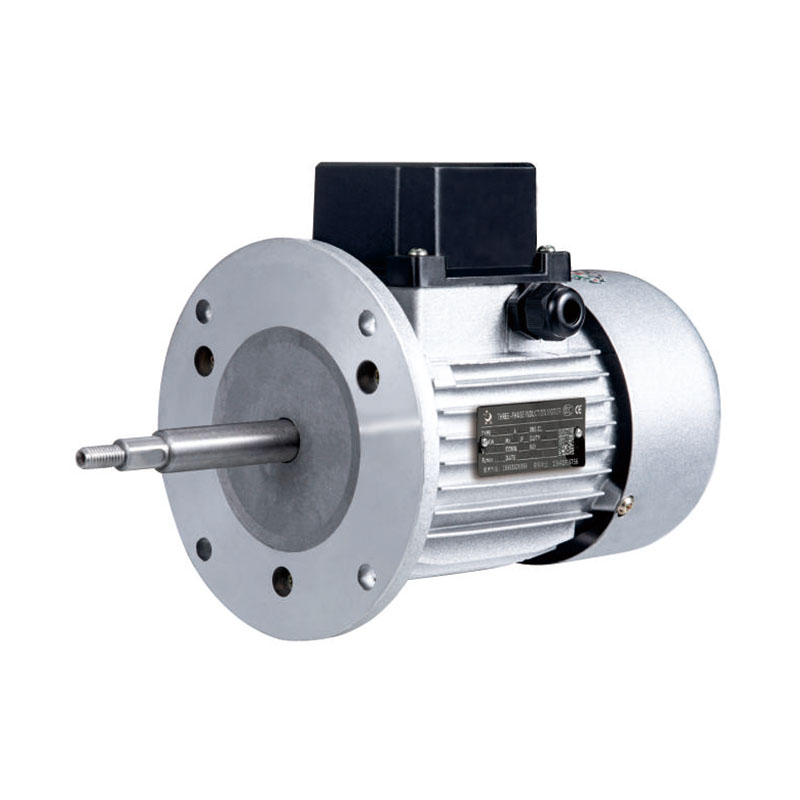

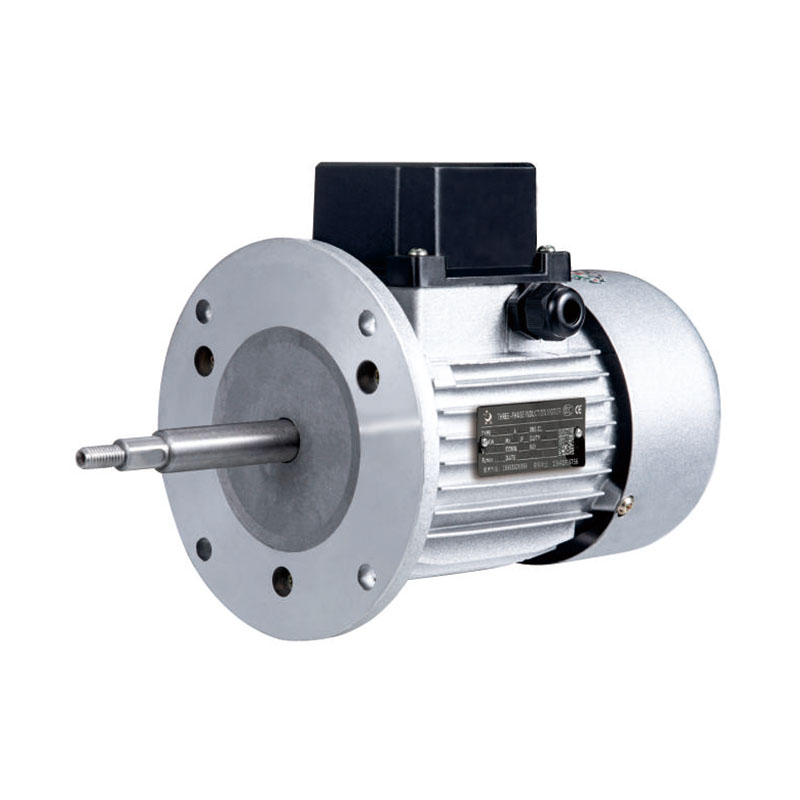

One of the notable advantages of the capacitor run asynchronous motor is its simple design that facilitates easy disassembly. Maintenance teams often face the daunting task of repairing complex machinery with intricate parts that are difficult to access. However, the capacitor run motor is engineered with a focus on simplicity. Its modular components allow for easy separation and reassembly, ensuring that routine inspections and repairs can be conducted quickly and with minimal disruption to ongoing operations.

By incorporating a modular design, manufacturers have made the capacitor run asynchronous motor far easier to maintain than many other types of motors. Components like capacitors, rotors, and stators can be accessed, replaced, or repaired without needing to disassemble the entire system. This streamlined approach significantly reduces the time and effort required for maintenance, which in turn leads to reduced downtime and improved efficiency for businesses relying on these motors.

Whether it is replacing a faulty capacitor or performing a routine inspection of the rotor, the capacitor run asynchronous motor is designed to allow technicians to carry out maintenance tasks without unnecessary complications. This ease of maintenance is particularly valuable in industries where machines run continuously, and minimizing interruptions is crucial for maintaining production schedules and meeting customer demand.

Readily Available Spare Parts: Minimizing Downtime

Another crucial feature that makes the capacitor run asynchronous motor a standout choice for industrial applications is the availability of spare parts. When a motor requires repairs, waiting for parts can often to prolonged downtime, which can be costly for businesses that depend on continuous operations. However, the widespread use and reliability of the capacitor run asynchronous motor have ensured that spare parts are readily available in the market.

Manufacturers of these motors prioritize the availability of spare parts, ensuring that essential components such as capacitors, bearings, and other critical elements can be easily sourced and replaced when needed. The quick availability of these parts reduces the time needed to repair or replace components, ensuring that downtime is kept to a minimum.

Additionally, because the motor’s modular design allows for easy replacement of individual parts, businesses can often avoid the need for full system replacements. This further reduces repair costs and ensures that the motor can be returned to operation with minimal interruption. Companies that rely on capacitor run asynchronous motors benefit from the peace of mind that comes with knowing their equipment can be repaired quickly and efficiently, without having to wait for back-ordered components.

Improved Operational Efficiency through Maintenance Ease

The reduced maintenance time and readily available spare parts translate directly into improved operational efficiency. As industries strive for higher levels of productivity, minimizing downtime is a key factor in achieving these goals. The ease of maintenance associated with the capacitor run asynchronous motor allows businesses to keep their equipment in top operating condition, ensuring that machines are available for use when needed.

This advantage is especially significant in industries where motors are essential to daily operations, such as in manufacturing plants, HVAC systems, and water treatment facilities. In these industries, every minute of downtime can result in substantial financial losses. By utilizing motors that are designed for ease of maintenance, businesses can ensure that they are minimizing these risks and the uptime of their operations.

Moreover, the capacitor run asynchronous motor’s high efficiency and durability also contribute to improved operational performance. Its ability to maintain a consistent output while consuming less energy reduces operational costs and enhances long-term reliability. When combined with its ease of maintenance, this motor becomes a cost-effective choice for businesses seeking to optimize both performance and reliability.

English

English Español

Español